Knitted wire mesh, a versatile material known for its flexibility and durability, is revolutionizing modern manufacturing processes across various industries. From EMI shielding to demister pads, its applications are diverse and crucial. This article explores the primary uses of knitted wire mesh, focusing on its innovative applications in contemporary manufacturing.

Understanding Knitted Wire Mesh

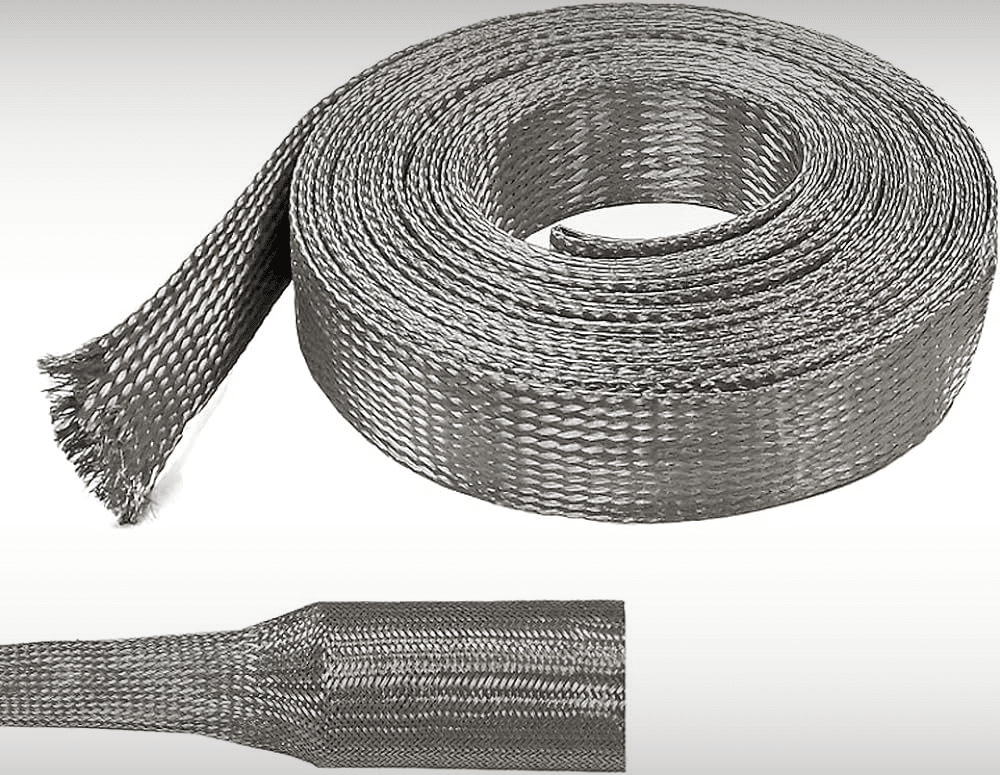

Knitted wire mesh is crafted from interlocking loops of wire, creating a porous and flexible structure that can be customized to meet specific industrial needs. Available in materials like stainless steel, it offers excellent corrosion resistance and durability, making it ideal for demanding applications in manufacturing.

Primary Uses of Knitted Wire Mesh

EMI Shielding

One of the key applications of knitted wire mesh is in electromagnetic interference (EMI) shielding. In industries such as telecommunications, electronics, and aerospace, where sensitive equipment is vulnerable to electromagnetic interference, knitted wire mesh acts as a protective barrier. Its intricate structure effectively absorbs and redirects electromagnetic waves, ensuring reliable performance and reducing the risk of signal interference.

Photo Courtesy: SRK Metals

Demister Pads and Mist Eliminators

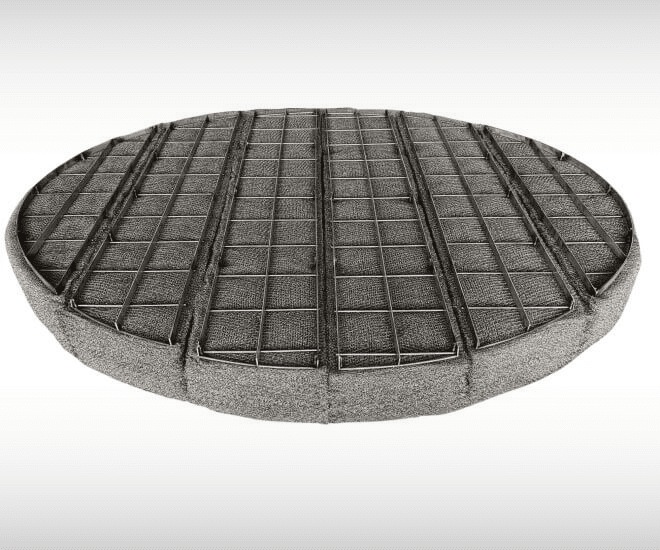

In chemical processing and oil refining industries, demister pads (or mist eliminators) are essential for separating liquid droplets from gas streams. Knitted wire mesh plays a critical role in demister pads by providing a high-surface-area barrier that captures and removes droplets from the gas flow. This process, known as coalescence, relies on the efficient design of knitted wire mesh to enhance separation efficiency and maintain operational integrity.

Innovative Applications in Manufacturing

Filtration Systems

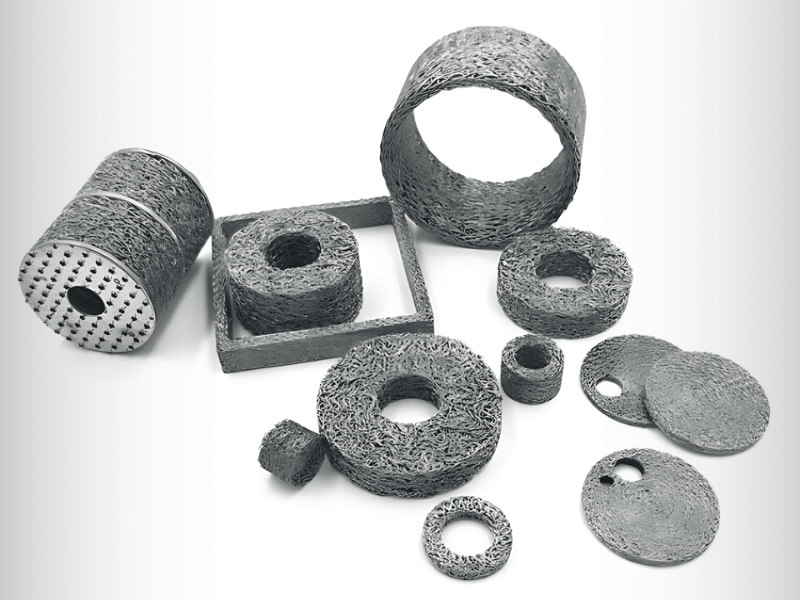

Knitted wire mesh is widely utilized in filtration systems where precision and efficiency are paramount. Whether filtering particulates from liquids or gases, its uniform structure allows for consistent performance and long-term reliability. Stainless steel knitted wire mesh, in particular, is favored for its resistance to corrosion and high temperatures, making it suitable for challenging industrial environments.

Photo Courtesy: SRK Metals

Sound and Vibration Control

In automotive and machinery manufacturing, knitted wire mesh is employed for sound and vibration control. By absorbing and dampening vibrations, it helps reduce noise levels and enhances the overall comfort and safety of vehicles and machinery. This application underscores the versatility of knitted wire mesh in improving product performance and user experience.

Knitted Wire Mesh Specifications and Materials

When selecting knitted wire mesh for specific applications, understanding its specifications and materials is crucial:

- Stainless Steel Knitted Wire Mesh: Offers superior corrosion resistance and durability, making it suitable for harsh environments.

- Demister Pads: Designed to efficiently separate liquids from gases, enhancing process efficiency and reducing maintenance.

Mist Eliminator Working Principle

The working principle of mist eliminators involves the use of knitted wire mesh to capture and coalesce liquid droplets from gas streams. As gas flows through the mesh, droplets adhere to the wire surfaces, eventually forming larger droplets that are drained away from the gas flow. This simple yet effective process ensures clean gas emissions and improves overall operational efficiency in various industrial applications.

Photo Courtesy: SRK Metals

Conclusion

Knitted wire mesh continues to be a cornerstone in modern manufacturing, offering unparalleled versatility and performance across a wide range of applications. From EMI shielding in electronics to demister pads in chemical processing, its innovative uses contribute to enhancing product quality, efficiency, and safety in industrial settings. As manufacturing technologies advance, so too will the applications and benefits of knitted wire mesh, ensuring its continued relevance and importance in the future of manufacturing.

Explore our range of knitted wire mesh solutions tailored to meet your manufacturing needs. Whether you require stainless steel knitted wire mesh for corrosion-resistant applications or demister pads for efficient mist elimination, we provide high-quality products designed to optimize your manufacturing processes. Contact us today to learn more about how knitted wire mesh can benefit your operations and improve your product performance.

Published By: Aize Perez